- Heat shrinkable plastic end cap for cable insulation

- 【Brief 】:

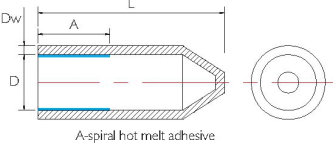

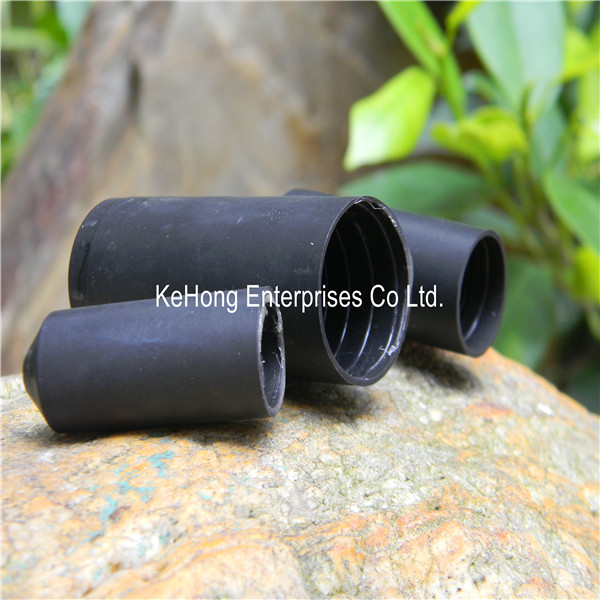

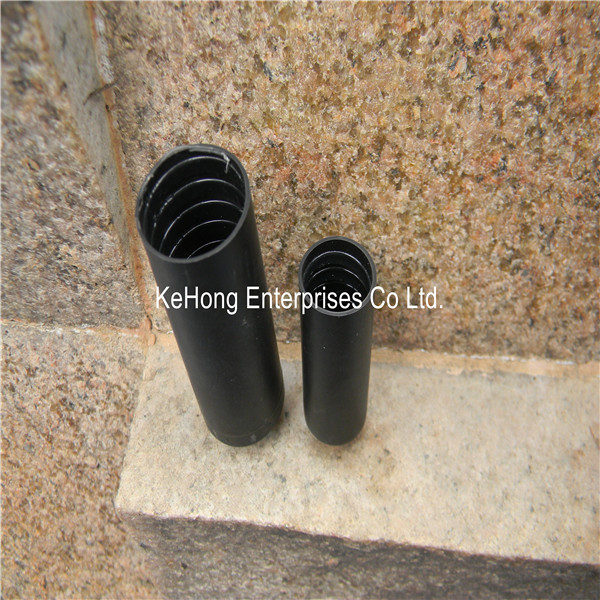

Heat shrinkable plastic end cap for cable insulation offers an economical sealing at the end of power cable with a completely watertight seal. The internal surface of the end cap has a layer of spiral coated hot melt adhesive, which retains its flexible properties after recovery. The cap is recommended for application both in open air and on underground power distribution cables.

Offering protection against oxidation, Ozone, UV-radiation

Coated with hot melt adhesive to ensure environment seal

Easily to fit into the cable end

Minimum fully shrink temperature: 120℃

- 【Series】:Heat shrink Cable End Cap

- Product description

Sizes(mm)

ID before Shrink(Min.mm)

ID after shrink(Max.mm)

After shrinking adhesive Length A (+/-10%,mm)

After shrinking Total Length L (+/-10%,mm)

After shrink Thickness Dw(mm)

Cable Dia (mm)

12

4

15

40

2.6

4-10.

CEC-14/5

14

5

18

45

2.2

5-12.

CEC-20/6

20

6

25

55

2.8

6-16.

C EC-25/8.5

25

8.5

30

68

2.8

10-20.

CEC-35/16

35

16

35

83

3.3

17 -30

CEC-40/15

40

15

40

83

3.3

18- 32

CEC-55/26

55

26

50

103

3.5

28 48

CEC-75/36

75

36

55

120

4

45 -68

CEC-100/52

100

52

70

140

4

55 -90

CEC-120/60

120

60

70

150

4

65-110

CEC-145/60

145

60

70

150

4

70-130

CEC-160/82

160

82

70

150

4

90-150

CEC-200/90

200

90

70

160

4.2

100-180

Extended length end caps

14

5

30

55

2.2

5-12

CEC-L-42/15

42

15

40

110

3.3

18-34

CEC-L-55/23

55

23

70

140

3.8

25-48

CEC-L-62/23

62

23

70

140

3.8

25-55

CEC-L-75/32

75

32

70

150

4.0

40-68

CEC-XL-75/36

75

36

70

170

4.2

45-68

CEC-L-105/45

105

45

65

150

4.0

50-90

Click here for Free Samples!!

3) Technical Data

|

Property |

Test Method |

Typical Data |

|

Operating temperature |

IEC 216 |

-55 to +110 ℃ ℃ |

|

Tensile strength |

ASTM D 638 |

>14MPa |

|

Elongation at break |

ASTM D 638 |

>400% |

|

Density |

ASTM D 792 |

1.05 |

|

Elongation at break after aging |

150 /168hrs.℃ |

>300% |

|

Dielectric strength |

IEC 243 |

>15kV/mm |

|

Volume resistance |

IEC 93 |

>1014 Ω. cm |