- Heat shrink tubing of busbar

- 【Brief 】:

Model:BSHST

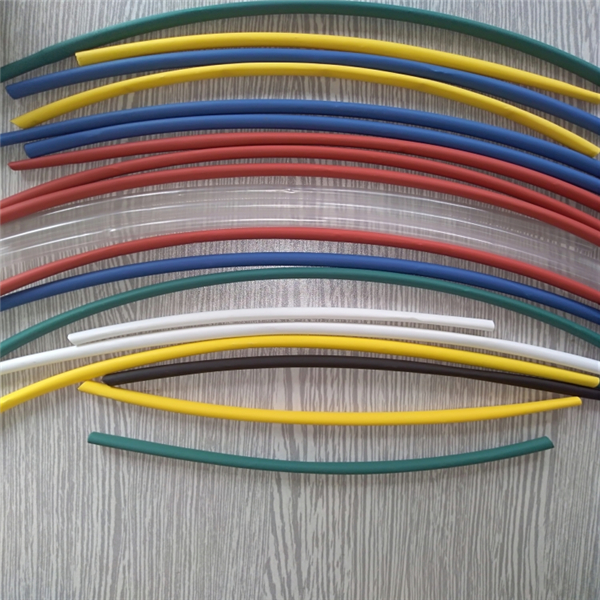

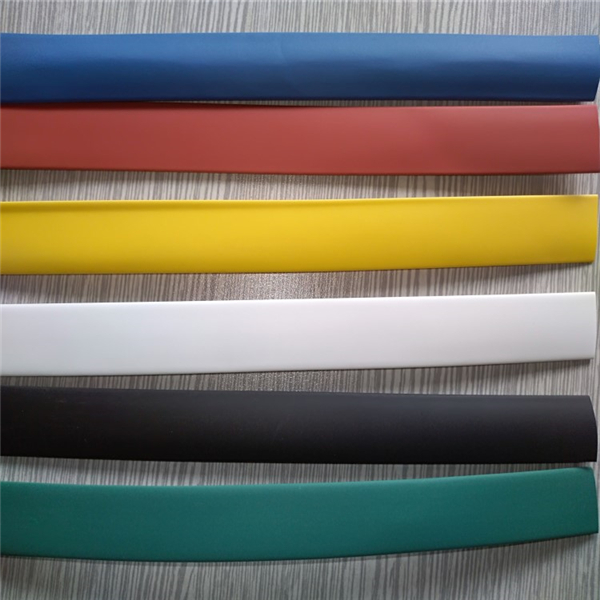

Made of cross linked polyolefin

High resistance to tracking, aging and erosion

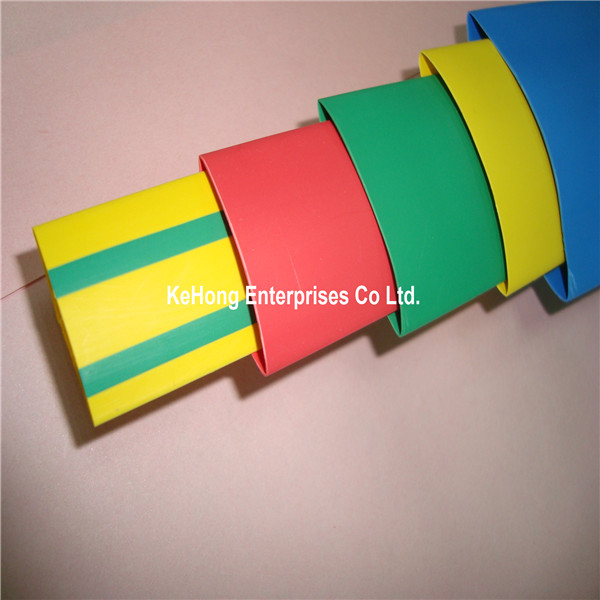

Used to offer insulation protection for busbar in switchgear and substation

Can be supplied in continuous length

Continuous operation temperature: -45℃ to 105℃

Shrink temperature: start at 110℃, and fully recovered at 130℃

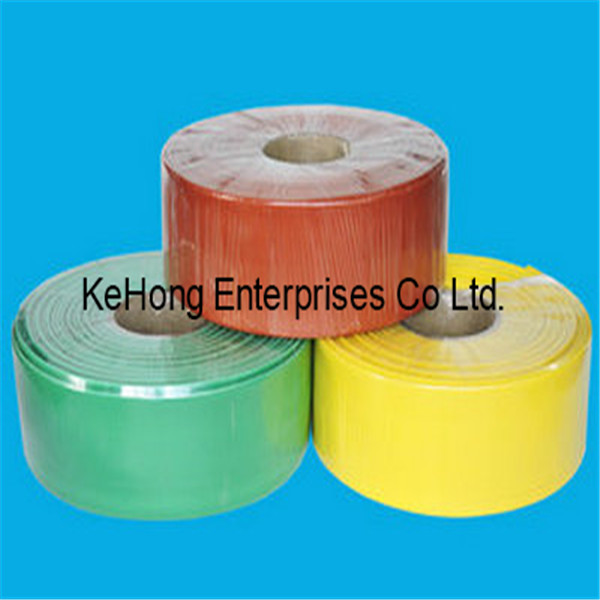

Color: yellow, red, green, blue, black - 【Series】:Single wall heat shrink tube

- Product description

Technical Data

Property

Test Method

Standard Value

Operation Temperature

IEC 216

-45℃ to 105℃

Tensile Strength

ASTM-D-2671

≥10MPa

Elongation at Break

ASTM-D-2671

≥400%

Tensile Strength after Aging

ASTM-D-2671

≥8MPa (130℃,168 hrs)

Elongation at Break

after Aging

ASTM-D-2671

≥320% (130℃,168 hrs)

Dielectric Strength

IEC 60243

≥25kV/mm

Volume Resistivity

IEC 60093

≥1×1014Ω·cm

Dielectric Constant

IEC 250

≤3.0

Longitudinal Shrinkage

ASTM-D-2671

Eccentricity

≤30%

Water Absorption

ISO 62

≤0.5%

Flammability (Oxygen Index)

IEC 4589

≥28

Copper Corrosion

ASTM-D-2671

No corrosion (130℃,168 hrs)

Cold Bend

ASTM-D-2671

No cracking (-40℃, 4 hrs)

Selection Table (10 kV heat shrink busbar sleeve)

As Supplied/mm

After Recovered/mm

Suitable for Rectangular

Suitable for Circular

ID(Min)

Wall Thickness

ID(Max)

Wall Thickness (±10%)

Busbar/mm

Busbar/mm

20

1.2

8

2.5

20

15

Ф25

25

1.2

11

2.5

1000

25

15

Ф30

30

1.2

13

2.5

1000

30

20

Ф40

40

1.2

16

2.5

1000

40

25

Ф50

50

1.3

18

2.7

1000

50

30

Ф65

65

1.3

28

2.7

1000

65

40

Ф75

75

1.3

31

2.7

1000

75

50

Ф85

85

1.3

36

2.7

1000

85

55

Ф100

100

1.3

42

2.7

1000

100

75

Ф120

120

1.3

48

2.7

1000

120

85

Ф150

150

1.3

62

2.7

1000

150

105

Ф180

180

1.3

73

2.7

1000

180

120

Ф210

210

1.3

84

2.7

1000

210

130

Ф230

230

1.2

85

2.7

1000

230

135

Ф250

250

1.5

102

3.7

1000

250

140

Ф300

300

1.6

110

3.9

1000

300

160

Ф350

350

1.2

142

3

1000

350

200

Ф400

400

1.2

160

3

1000

400

260

Ф450

450

1.4

193

3.2

1000

450

300

Ф500

500

1.2

193

3.2

1000

500

330